Before the COVID-19 pandemic prompted Liberty University to move spring classes online in March, rising senior mechanical engineering student Carson Farmer and mathematics student Nathanael Gentry were conducting research as part of a robotics research group in the School of Engineering.

As the semester continued, with most students completing their studies online from the comforts of their homes, those experiments temporarily ceased as students were no longer allowed to work in close proximity out of the labs in DeMoss Hall.

“This led us to begin thinking, ‘How can we begin to do some of this testing remotely … to connect Nathanael from his computer in South Carolina to equipment located here in our lab in Lynchburg, Virginia?’” Farmer said. “That is how the remote lab system started. It took a lot of creativity.”

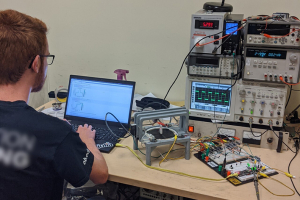

Under the direction of Dr. Hector Medina, their faculty advisor, the students are studying the control of soft robotics with the use of machine learning, a form of artificial intelligence that trains machines to “think.” Their work is in mechatronics, a field that combines mechanical, electrical, and computer engineering, as well as computer science. Using computer-guided instrumentation, they apply a varying electrical field to a soft actuator such as an electroactive polymer to simulate the muscular movements of a living organism.

“The idea is to try to mimic what nature does, what God’s creation does, specifically in the area of soft tissue,” Medina said. “Traditional robotics are very stiff because they depend on stiff actuators like traditional motors. Soft robotics use more flexible materials, with which we can imitate more what happens in nature and natural systems. The equations that are used to accurately model the behavior of these soft materials can be extensive and complicated. You have to create a very robust programming control scheme based on very robust mathematical relationships.”

That made the conversion from in-lab experimentation to remote work all the more challenging, but

Farmer was up to the task, teaching Gentry to write code that would create interfaces between the micro-controllers and measuring equipment.

Gentry, who started at Liberty majoring in computer science and has a knack for programming, caught on quickly.

“My research for this project is understanding how we can use machine learning, specifically reinforcement learning, to develop a control policy for this highly non-linear and viscoelastic material,” said Gentry, who also enjoys computer modeling and statistical work.

He used Python software to run code remotely through the JupyterLab server connected to the serial interface, which manipulates the soft actuator, in this case a carbon-coated dialectric elastomer.

“In order for us to be able to have a baseline to start from, we had to collect a lot of training data … and then run analysis on that data,” Gentry said, noting that a laser optical sensor collects information from the elastomer frame. “To be able to do this remotely, I needed to be able to control the elastomer, pass voltage to it, and then measure its response.”

The remote lab tests, often running hours at a time, have been successful. With automated failsafe measures in place to prevent damage to the equipment if it malfunctions, the experiments can be executed smoothly without either student physically in the lab.

“This is the demonstration of the creativity of the students in the middle of a pandemic, how they could incorporate this remote lab component into the tests that they needed to run,” Medina said. “It allows my students doing research to continue collecting data despite the COVID-19 restrictions and serves as a proof of concept that certain things can be done if, for any reason, you have to work remotely.”

Gentry has benefited greatly from being a part of the research group.

“For me, working on this project has made me more technically minded and interested in how computers can interface with the real world, which is very much what robotics is about,” he said.

Farmer plans to continue his mechanical engineering studies in graduate school before potentially going into the field of robotics, working with soft actuator systems.

“This could begin ushering in a new era where computers are controlling our experiments,” he said. “We are just at the forefront of what this could possibly look like.”

Medina foresees both machine learning and the remote lab model making waves for future technology innovation.

“This is a hot topic,” he said. “A lot of people are trying to move in that direction, especially interaction between humans and a robotic system. (Dielectric elastomers) have medical applications, also. So, another potential project that we are going to be exploring this fall is to use this material to help people with Parkinson’s Disease.”

Medina is thankful to Liberty’s Center for Research and Scholarship for its continuous support. He plans to continue to incorporate remote lab work through the fall semester due to social distancing restrictions.

“This fall, we will use some of the lessons learned from these remote lab activities to teach more than 40 mechanical engineering students taking Dynamic Systems about controls using machine learning techniques,” he said.

The mechatronics lab is one of several labs in Liberty’s School of Engineering, located on the third floor of DeMoss Hall. Thermal fluids, electrical engineering, mechanical, 3D printing, machine shop, faculty research/EMC, software, network engineering, and the multipurpose lab are the others, all connected by Liberty’s advanced fiber-optic network that provides access to the Internet and various networked applications.

"soft" - Google News

August 28, 2020 at 02:00PM

https://ift.tt/2EMkLgG

Students use remote lab techniques to study control of soft robots with machine learning - Liberty - Liberty News

"soft" - Google News

https://ift.tt/2QZtiPM

https://ift.tt/2KTtFc8

Bagikan Berita Ini

0 Response to "Students use remote lab techniques to study control of soft robots with machine learning - Liberty - Liberty News"

Post a Comment