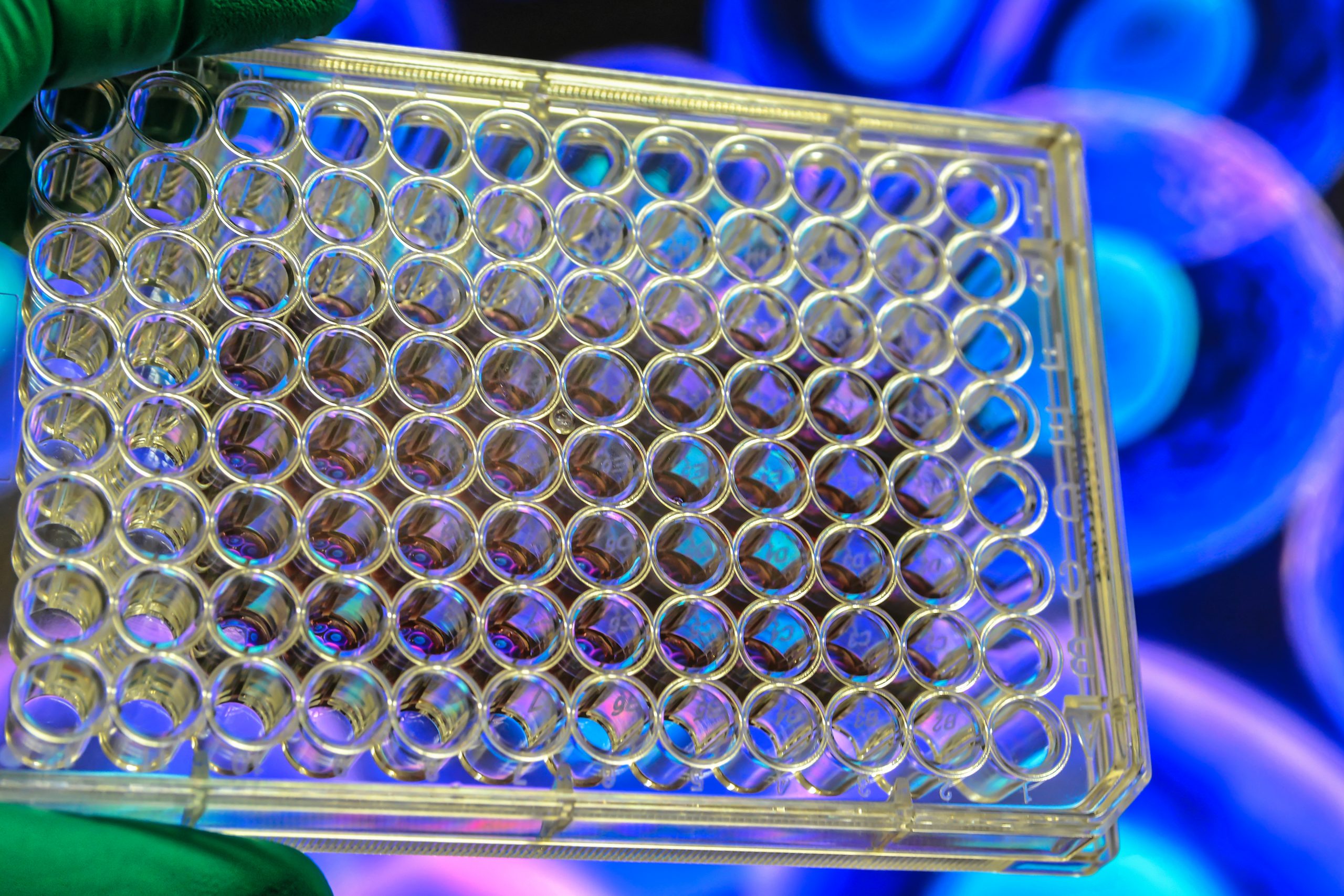

Biomass monitoring is mandatory for cGMP Chinese hamster ovary (CHO) cell cultures, with viable cell density (VCD) or viable cell volume (VCV) as the predominant approaches. A recent paper by scientists at Roche Diagnostics makes the case for VCV using a soft sensor based on oxygen uptake rate (OUR). Researchers examined fourteen continuous single-use processes run under identical conditions but with differently-expressing cell lines, and found good correlation between soft sensor outputs and quantities obtained through a reference method.

VCD is commonly measured using automated cell counting devices, which rely on Trypan blue staining to identify living and dead cells. Algorithms then automatically evaluate the generated images with (reference) stained and unstained cells. VCV can also be determined using these methods, according to Roche Bioprocess Engineer Tobias Wallocha. “AVC times viable cell density equals VCV, which is therefore a more comprehensive description of biomass. VCD alone is only a coarse measure, since even small changes in average cell diameter result in large differences in cell volume.”

Despite the urgent need for speed and co-location of culture and analysis, this is generally not possible through cell counting. “You have to take a sample, dilute it manually, and transfer it to the device,” Wallocha explains. “Such a procedure is error-prone and only provides one measurement point—no continuous description of your biomass. Furthermore, automated cell counting lacks accuracy.”

What is true for batch cultures is multiply-so for perfusion. “Continuous processes have completely different requirements regarding process control, automation, sterility etc. In terms of biomass measurement, continuous processes could therefore benefit from real-time, online biomass measurements through, for example, soft sensors as described in our paper,” explains Wallocha.

Instead of the usual hardware and manual steps, the Roche device uses a software-based prediction model to estimate a process variable—biomass—that is otherwise difficult to quantify online or in real-time.

“The off-gas-based soft-sensor for real-time biomass and metabolism prediction is a robust, easily implemented technique for single-use or stainless steel bioreactors,” Wallocha tells GEN. “The fundamental correlation of biomass growth and increasing oxygen demand can be used, optimized and extended to generate profound real-time knowledge on diverse bioprocess variables such as biomass and metabolic nutrient rate. Due to the complexities of modern bioprocesses, process analytical techniques should be as comprehensive as possible to ensure high quality products and reproducible processes.”

"soft" - Google News

January 25, 2022 at 08:00PM

https://ift.tt/32Ag8Tk

Soft Off-Gas Sensor for CHO Cultures - Genetic Engineering & Biotechnology News

"soft" - Google News

https://ift.tt/2QZtiPM

https://ift.tt/2KTtFc8

Bagikan Berita Ini

0 Response to "Soft Off-Gas Sensor for CHO Cultures - Genetic Engineering & Biotechnology News"

Post a Comment